Abstract

Automate Surgical Tasks for A Flexible Serpentine Manipulator via Learning Actuation Space Trajectory from Demonstration

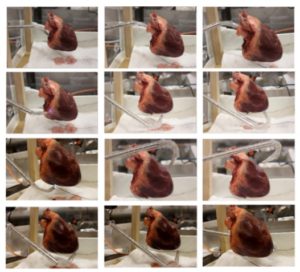

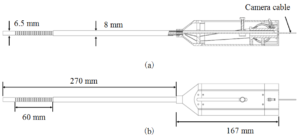

Background: Accurate motion control of flexible surgical manipulators is crucial in tissue manipulation tasks. Tendon-driven serpentine manipulator (TSM) is one of the most widely adopted flexible mechanisms in MIS for its enhanced maneuverability in torturous environment. TSM, however, exhibits high nonlinearities and conventional analytical kinematics model is insufficient to achieve high accuracy.

Methods: To account for the system nonlinearities, we applied data driven approach to encode the system inverse kinematics. Three regression methods: Extreme Learning Machine (ELM), Gaussian Mixture Regression (GMR) and K-Nearest Neighbors Regression (KNNR) were implemented to learn a nonlinear mapping from the robot 3D position state to the control inputs.

Results: The performance of the three algorithms were evaluated both in simulation and physical trajectory tracking experiments. KNNR performs the best in the tracking experiments with the lowest RMSE of 2.1275mm.

Conclusions: The proposed inverse kinematics learning methods provide an alternative and efficient way to accurately model the challenging tendon driven flexible manipulator.

Keywords: Tendon-driven serpentine manipulator; surgical robotics; Inverse kinematics; Heuristic Methods

Demo video at:

Publications

- W. Xu; J. Chen; H. Y. Lau & H. Ren Data-driven Methods towards Learning the Highly Nonlinear Inverse Kinematics of Tendon-driven Surgical Manipulators International Journal of Medical Robotics and Computer Assisted Surgery , 2016, 1-13

- W. Xu; J. Chen; H. Y. Lau & H. Ren Automate Surgical Tasks for A Flexible Serpentine Manipulator via Learning Actuation Space Trajectory from Demonstration ICRA2016, IEEE International Conference on Robotics and Automation, 2016, –